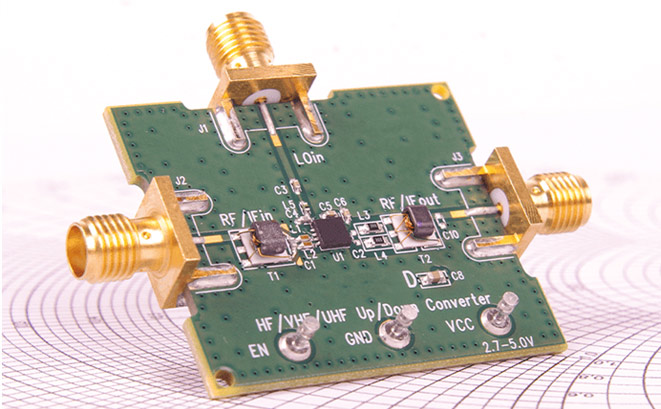

Radio frequency printed circuit boards (RF PCBs) are an exciting, fast growing sector of the PCB manufacturing

industry.They are also incredibly complex with a dizzying range of options. The engineers at Lingtech-PCB can assist

you with every step of the fabrication and assembly process, including material selection and key RF PCB

manufacturing challenges to be aware of.

In general terms, the PCB industry considers an RF circuit board to be any high frequency PCB that operates above

100MHz.Within the radio frequency class, anything above 2GHz is a Microwave PCB.

The main difference between RF circuit boards and Microwave PCBs is in the radio frequency in which they operate.

Microwave PCBs are classified as any RF circuit board operating above 2GHz.

RF circuit boards and Microwave PCBs are used for communication signals in any application that requires receiving

and transmitting radio signals. For example, some common applications are cell phones and radar installations.

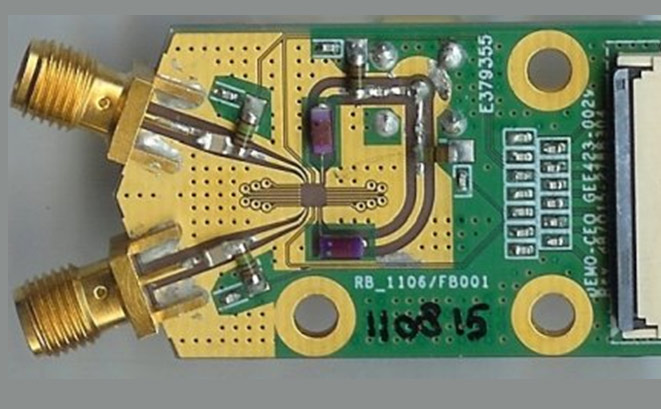

RF circuit boards, and Microwave PCBs, are especially difficult to design compared to traditional PCB layouts.

This is due to the problems that could arise in receiving or transmitting the radio signals. Some of the main

problems are noise sensitivity, and tighter impedance tolerances

Compared to traditional circuit boards, radio and microwave signals are very sensitive to noise and also require

much tighter impedance tolerances. The best solution for these problems is to utilize ground plans and use a generous

bend radius on impedance controlled traces. These solutions will ultimately allow the RF/Microwave PCB to achieve

the best performance.

RF boards have a multitude of different applications, including wireless technologies, smart phones, sensors,

robotics and security. With the advent of new technologies that are pushing the limits of electronics, the demand

for RF boards is on the rise.Finding a capable RF PCB manufacturer is critical to make sure the boards are

fabricated to high quality standards and on-time. Our reputation speaks for itself. We pride ourselves on bringing

the most demanding layout concepts to reality.

We can help with everything from saving cost on a simple board to manufacturing advice for cutting edge,

fifty layer designs. To simplify your search, here are several recommendations for materials based on application

and manufacturability:

Important Note: Within every industry, there is a wide range of applications, demands, and budgets.

The table below provides general recommendations, but to find the best PCB materials for your specific project,

please contact our engineering staff.