Heat generated by circuit mainly derives from component heat, PCB board heat and heat as a result of exterior conduction among which component heat accounts for the majority. Therefore, components’ thermal dissipation issue receives the most concern during component layout and PCB design. Thermal resistance plays a significant role in thermal design and the aim of thermal design is to reduce thermal resistance conducted on the path of thermal conduction with heat quickly conducted to heat sink such as radiator. Overall thermal resistance between electronic component and heat sink can be classified into device-level, assembly-level and system-level. Device-level thermal resistance is also called internal resistance while assembly-level resistance called exterior resistance and system-level resistance called final resistance. Relationship between internal and exterior resistance and Tj of components is equivalent to that between component Tj and thermal resistance, conforming to the following formula:

Tj=Pd x (Rjc+Rcs+Rsa)+T0

In this formula, Tj refers to component junction temperature; Pd refers to device power; Rjc, Rcs and Rsa respectively refer to thermal resistance from junction to enclosure, enclosure to heat sink and heat sink to complete appliance. T0 refers to initial temperature and Rjc is a fixed characteristic value. Thus, thermal resistance reduction can only be achieved from the perspectives of Rcs and Rsa.

Device assembly modes play a significant role in thermal dissipation and different types of assembly modes require different thermal dissipation methods.

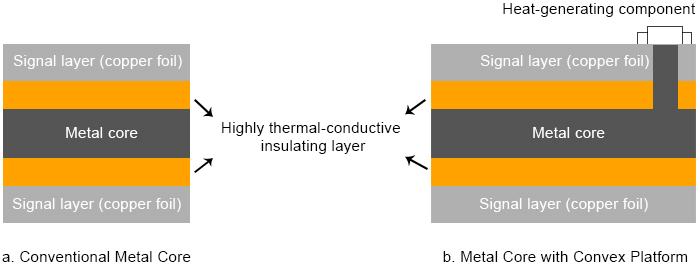

• Convex Platform Structure

When component shell directly contacts with circuit board and is assembled on the front side, coverplate convex platform should be leveraged for thermal dissipation. Convex-platform thermal dissipation refers to the process that a convex platform for thermal dissipation is added to corresponding coverplate in accordance with heat sink positions in circuit with thermal-conductive insulating mat used to be contacted with convex platform.

This thermal dissipation mode acquires cooperative work of structure and PCB board design. Convex platform count, positions, height, area and thermal-conductive mat thickness are all closely related with circuit board performance. Plus, assembly deviation has to be taken into consideration as well. So this mode brings many difficulties to PCB design, PCB manufacturing and PCB assembly (PCBA).

• Thermal Conductive Tape

If component pins are directly soldered onto PCB board without component shell directly contacted with circuit board, thermal conductive tape can be leveraged for thermal dissipation. Thermal conductive tape is usually made of copper, featuring two assembly types. One is to get thermal conductive tape assembled on component top with the other end connected with heat sink. The other is to assemble components onto circuit board through thermal conductive tape with the other end connected with heat sink. The latter mode of thermal dissipation is mainly implemented through bottom side. Adhesive thermal-conductive insulating mat can be used between component and thermal conductive tape.

This mode calls for structural assembly between components and thermal conductive tape that should both maintain a good contact with thermal-conductive mat and components and should not impose too large stress to component pins. To fix thermal conductive tape, fixed locating holes should be made on circuit board so that PCB tracing and layout will be badly affected. Therefore, this mode doesn’t work for high density board.

Furthermore, component pins will be affected when thermal conductive tape is vibrating, which has to be carefully considered.

• Thermotube

Thermotube takes advantage of evaporative refrigeration with thermotube two-end temperature difference extremely large so that heat can be fast conducted. Generally speaking, thermotube is composed by tube shell, wick and end cover. Internal thermotube features a negative pressure state with some liquid with low boiling point filled in. Moreover, this type of liquid is easy to be volatilized. Liquid absorption core is available on tube wall, made from capillary material. One end of thermotube is for evaporation while the other for condensation. When evaporation part of thermotube is heated, liquid in capillary will be evaporated instantly and steam flows to the other part under micro stress with heat generated and recondensed to liquid that will flow back to evaporation part of thermotube under capillary stress.

Although thermotube features dramatically thermal dissipation capability, it hasn’t developed maturely enough to be accepted by small components. Therefore, there’s still a long way for thermotube to go in thermal dissipation of PCB boards.